What is Shrinkwrap and how does it work?

Shrinkwrapping is a heat-activated process that uses a thin clear plastic film (PVC or polyolefin) to seal and present packages. The package is placed between 2 layers of film, then when heat is applied this thin film shrinks tightly around the packaging holding the goods together neatly and securely.

Why use Shrinkwrap film?

Shrinkwrapping is a great way to package printed products – it’s quick and easy to do and the end result is neat and professional. Printed goods often need to be packaged in varying quantities, and using a shrinkwrapper along with good quality shrinkfilm offers versatility that “box ‘n’ tape” simply cannot match.

Does investing in a shrinkwrapper increase profitability?

This is a common question when any printroom is considering investing in shrinkwrapping equipment. It could be argued that shrinkwrapping doesn’t add anything to the value of the printed goods so is therefore an unnecessary extra expense; however, in our experience any printroom that possesses a shrinkwrapper uses it all the time to great advantage. Once the initial investment has been made, the ongoing advantages are a) that you have a low cost, quick, professional packaging method available for use at any time, and b) your customers receive their printed goods looking good and well packaged without damage.

What Shrinkwrapper should I buy?

This depends largely on the volume of goods to be wrapped and speed of output required.

A couple of popular choices:

The CTS5000 Chamber Shrink Wrapper is one of the most popular for small to medium volume users, an ideal fit in any printroom.

· Simple one man operation

· Trims, seals and shrinks all in one cycle

· Approx output 300 packs per hour

· Accepts film widths up to 550mm

· Uses polyolefin or PVC shrink films

· Fully featured with digital control panel

· Seal only option

· Compact - Dimensions - H1230mm x W1165mm x D750mm

The CT9000 Semi-Automatic sealer/tunnel shrink tunnel is for higher volume users with potential output of up to 700 items per hour.

· Simple one man operation

· Trims, seals and shrinks all in one pass

· Approx output 700 packs per hour

· Accepts film widths up to 600mm

· Max pack size (approx) 550mm x 400mm x 150mm

· Adjustable L-Sealer with fully controllable sealing cycle

· Quiet running shrinktunnel with adjustable conveyor height

· 3 phase power supply

· Dimension 2610mm L x 810mm W x 1570 H

· Uses polyolefin or PVC shrink films

What shrinkfilm should I order?

There are also two types of shrinkfilm available for use on the machines above.

PVC shrinkfilm shrinks easily with a clean, professional finish, however it is fairly brittle and it will emit a certain amount of odour when shrinking; also PVC shrinkfilm will leave residue on your shrinkwrapping machine.

Polyolefin Shrinkfilm is a type of shrinkfilm that is odourless, environmentally friendly and won't leave a residue on your machine, meaning less downtime and maintenance. Polyolefin Shrinkfilm is also much more pliable than PVC meaning it’s far less likely to crack or fall apart which would of course end up damage to your printed product. The slight downside of polyolefin is that it doesn’t shrink quite as readily as PVC.

Both shrinkfilms work out about the same cost per square meter and also shrink about the same temperature.

What size film should I order?

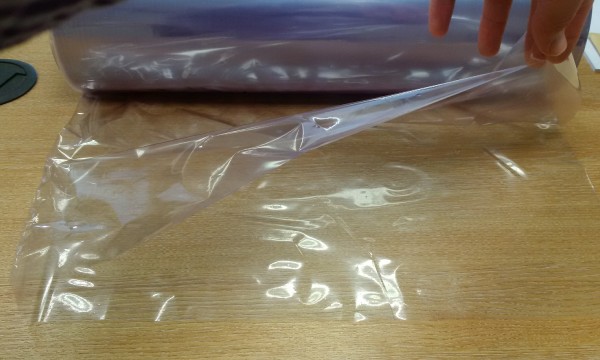

All our shrinkfilm comes with centrefold in various widths so if you see 450/900, what this means is the film on a 450mm wide roll is folded in half to make packing easier as shown in the pictures below. Here is a calculation you can make to determine what width of film roll you should order.

Centerfold Shrink Film Measurement Formula - Width + Depth x 2 x 1.1÷2 = Centerfold Film Width Needed